LED lamp beads are a crucial component in modern lighting solutions, known for their energy efficiency, long lifespan, and environmental benefits. However, achieving optimal performance and longevity requires careful consideration of several factors during the design, manufacturing, and usage stages. This article explores strategies to improve the quality and lifespan of LED lamp beads effectively.

1. Material Selection

Choosing high-quality materials is fundamental to enhancing the performance and durability of LED lamp beads. The key materials include:

- Semiconductor Materials: The core of an LED is its semiconductor material, typically made from compounds like gallium nitride (GaN). Selecting high-quality semiconductor materials ensures efficient light emission and better thermal management.

- Substrate Materials: Materials such as sapphire, silicon carbide (SiC), or gallium nitride (GaN) on silicon provide a stable base for LED construction and are crucial for heat dissipation.

- Encapsulation Materials: Silicone or epoxy resins are commonly used to encapsulate LEDs, protecting them from environmental factors. High-quality encapsulants with good UV resistance and optical clarity are essential for maintaining light output over time.

2. Efficient Thermal Management

Thermal management is a critical factor in extending the lifespan of LED lamp beads. Excessive heat can degrade LED materials, leading to reduced brightness and premature failure. Effective thermal management strategies include:

- Heat Sink Design: Incorporating efficient heat sinks made of materials like aluminum can dissipate heat away from the LED chips.

- Thermal Interface Materials (TIMs): High-conductivity TIMs enhance heat transfer between the LED package and the heat sink.

- Proper Circuit Design: Designing circuits that minimize power loss and heat generation helps maintain a stable operating temperature.

3. Quality Control in Manufacturing

Stringent quality control processes during manufacturing are essential to ensure the reliability and consistency of LED lamp beads. Key aspects include:

- Wafer Inspection: Regular inspection of semiconductor wafers for defects ensures only high-quality materials are used.

- Precision in Dicing and Bonding: Accurate LED chip dicing and die bonding prevent damage to the chips, which can affect their performance.

- Automated Testing: Automated optical and electrical testing systems help identify defects early in the production process, reducing the risk of faulty LEDs reaching the market.

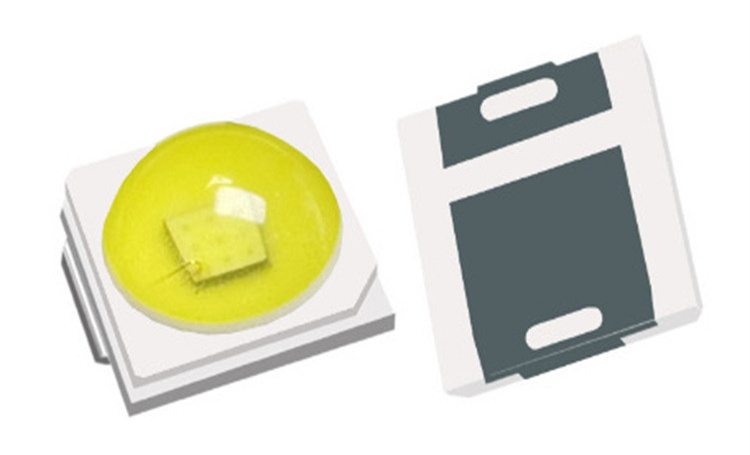

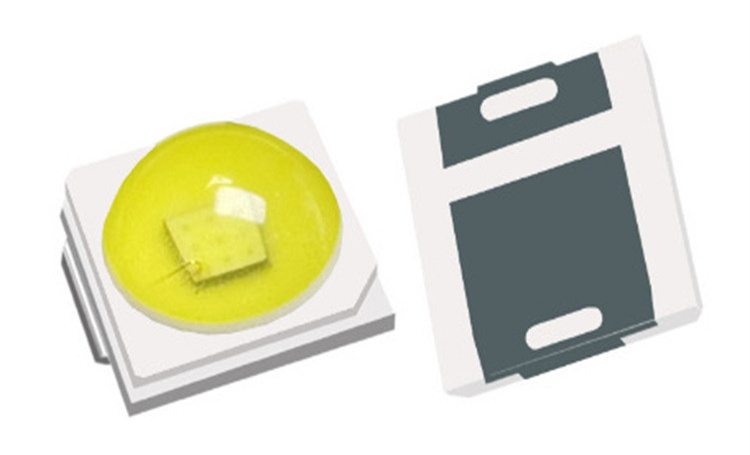

4. Phosphor Coating and Encapsulation

The phosphor coating converts the light emitted by the LED chip into the desired color. The quality and uniformity of the phosphor coating significantly impact the color consistency and efficiency of the LED. Best practices include:

- Consistent Phosphor Application: Ensuring a uniform phosphor layer across all LEDs helps maintain consistent color output.

- Curing and Encapsulation: Proper curing processes ensure the stability of the phosphor coating, while high-quality encapsulation protects the LED from moisture and physical damage.

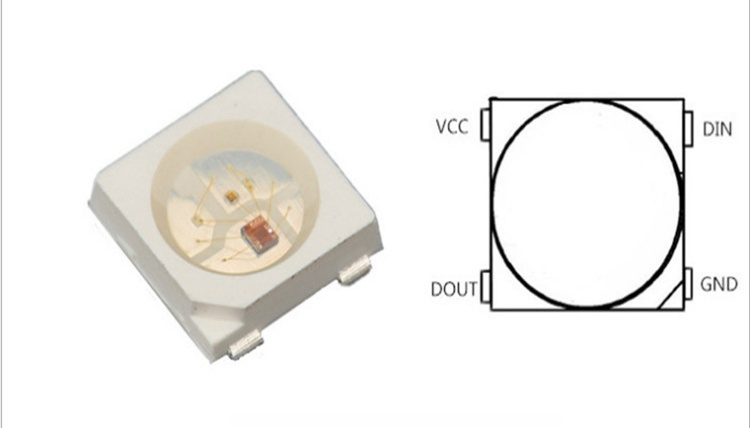

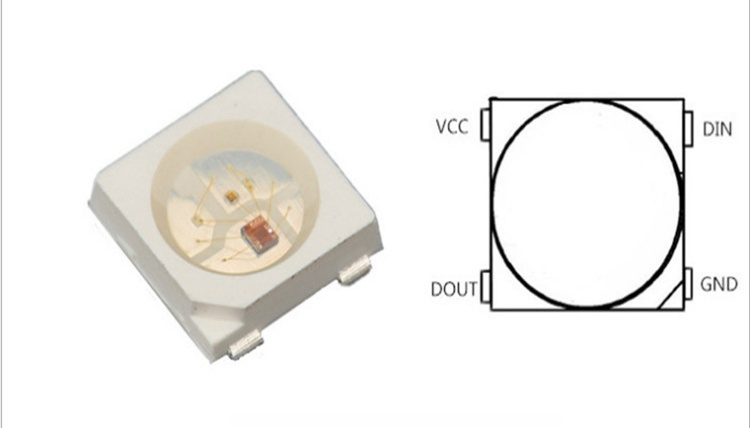

5. Electrical and Optical Design Optimization

Optimizing the electrical and optical design of LED lamp beads enhances their efficiency and lifespan. This involves:

- Current Regulation: Implementing drivers that regulate current to prevent overdriving, which can shorten the LED's lifespan.

- Optical Design: Using lenses and reflectors to optimize light distribution reduces the need for excessive power and extends the LED's operational life.

6. Proper Usage and Maintenance

The end-user can also take steps to extend the lifespan of LED lamp beads. These include:

- Correct Voltage and Current: Ensuring that LEDs are operated within their specified voltage and current ranges prevents overheating and degradation.

- Adequate Ventilation: Installing LEDs in environments with adequate airflow prevents overheating.

- Regular Cleaning: Keeping LED fixtures clean from dust and debris ensures optimal light output and heat dissipation.

Conclusion

Improving the quality and lifespan of LED lamp beads requires a holistic approach that includes careful material selection, efficient thermal management, stringent quality control, and proper design and usage practices. By addressing these factors, manufacturers can produce LED lamp beads that deliver high performance and durability, offering consumers reliable and long-lasting lighting solutions.

If you need assistance from professionals, feel free to contact us. We are here to provide you with expert help and support for all your needs. Don't hesitate to reach out to our team for personalized assistance and solutions. We look forward to serving you.