High Quality OEM/ODM LED Strip Manufacturer

High Quality OEM/ODM LED Strip Manufacturer

May 20, 2024 486

COB (Chip On Board) LED strips have become a popular choice for both home and commercial lighting due to their high brightness and uniform light output. However, many users encounter a common question during installation: can you cut COB LED strips? The answer is yes, but it requires following specific steps and precautions. This article will provide a detailed guide on how to cut COB LED strips, ensuring a simple and practical approach.

COB LED strips are lighting devices where multiple LED chips are directly mounted onto a single substrate. Compared to traditional SMD (Surface-Mounted Device) LED strips, COB strips have a denser arrangement of light sources, offering higher efficiency and more uniform light without visible spots.

Yes, COB LED strips can be cut to fit your specific lighting needs. By cutting the strips, you can adjust their length to suit various installation environments. However, cutting COB LED strips requires some skill and attention to ensure they continue to function correctly after modification.

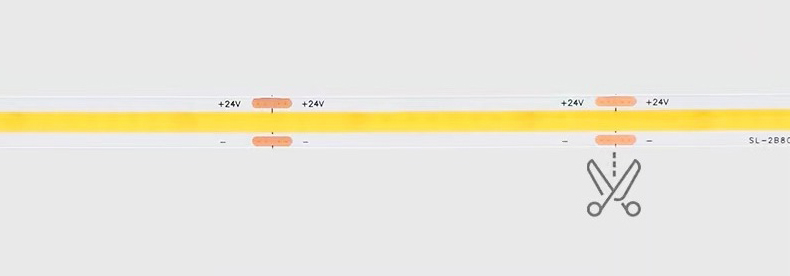

Before cutting, locate the cutting points on the strip. COB LED strips typically have marked cutting points at regular intervals (such as every 5 cm or 10 cm). These points are often indicated by a dashed line or scissor icon. Cutting at these marked points ensures the circuit remains intact.

You will need some basic tools to cut the COB LED strip, including a pair of sharp scissors or a blade, and insulation tape or heat shrink tubing. Ensure your tools are clean and sharp to make precise cuts.

Carefully cut along the marked cutting point. Ensure the cut is clean and straight, avoiding damage to the surrounding circuitry and components.

After cutting, the exposed wires at the cut end need to be insulated to prevent short circuits or damage. Use insulation tape to wrap the exposed wires or apply heat shrink tubing for a secure seal.

After cutting and insulating the ends, test the strip by connecting it to a power source to ensure it works correctly. If any part of the strip is not lighting up or working properly, check the connections at the cut points and make necessary adjustments.

Always cut along the marked cutting points. Random cuts can damage the strip’s circuitry, rendering it non-functional.

Perform the cutting operation with the power off to avoid electrical shock. Properly insulate the exposed wires after cutting to prevent short circuits and electrical hazards.

Different models and brands of COB LED strips may have varying cutting intervals and marking methods. Always refer to the product manual for specific information before cutting.

Before making major cuts, perform a test cut on a small section to ensure you understand the process and to avoid potential issues with a larger section.

Cutting COB LED strips is straightforward but requires attention to detail. By following the correct procedure, you can easily adjust the strip length to meet various installation needs and achieve desired lighting effects. Whether for home decoration or commercial lighting, cutting COB LED strips offers flexibility and customization for your design. If you are not confident in performing the cut yourself, consider seeking guidance from a professional to ensure safety and effectiveness.

If you need assistance from professionals, feel free to contact us. We are here to provide you with expert help and support for all your needs. Don't hesitate to reach out to our team for personalized assistance and solutions. We look forward to serving you.

Our sales will reply to you within 2 hours.