High Quality OEM/ODM LED Strip Manufacturer

High Quality OEM/ODM LED Strip Manufacturer

October 10, 2020 501

COB (Chip on Board) LED technology has become a key player in modern lighting solutions, renowned for its high efficiency, uniform light distribution, and excellent thermal performance. COB LED strips, which use this technology, are popular in various lighting applications, ranging from residential to commercial environments. This article provides a comprehensive overview of the COB LED strip manufacturing process, detailing each critical step and its importance.

The first step in manufacturing COB LED strips is the fabrication of semiconductor wafers. These wafers are usually made from materials such as gallium nitride (GaN), silicon carbide (SiC), or sapphire, chosen for their superior semiconductor properties.

After the epitaxial layers are complete, the wafer is diced into individual LED chips. This process involves:

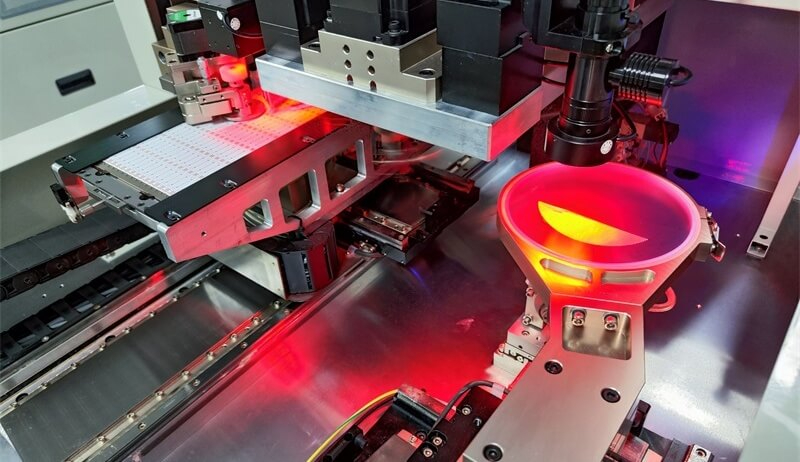

Once the LED chips are prepared, they need to be mounted onto a substrate in a process known as die bonding. This stage includes:

Wire bonding establishes electrical connections between the LED chips and the circuit on the substrate. This process involves:

To produce white light or other desired colors, a phosphor coating is applied over the LED chips. This process includes:

Encapsulation is crucial for protecting the LED chips and wiring from environmental factors like moisture, dust, and mechanical damage. This step involves:

Effective thermal management is essential for maintaining the performance and longevity of COB LEDs. This process includes:

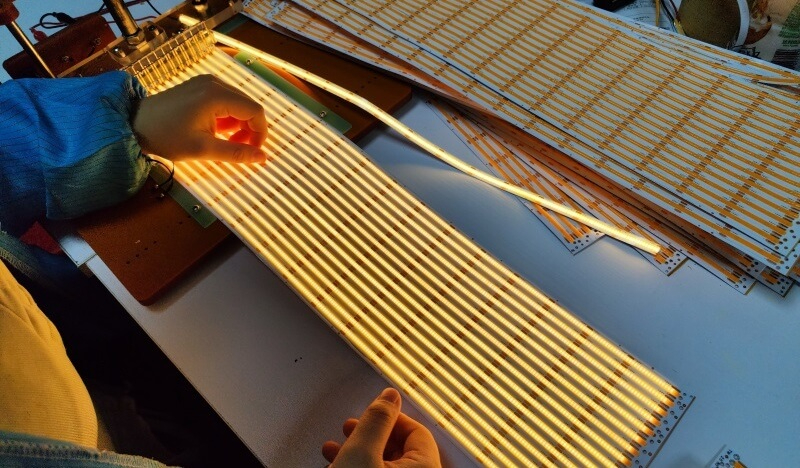

Before COB LED strips are ready for market, they undergo rigorous testing and quality control to ensure they meet all required specifications. This stage includes:

Once the COB LED strips pass all quality checks, they proceed to final assembly and packaging. This stage involves:

The COB LED strip manufacturing process is a sophisticated and precise procedure, encompassing various critical steps from wafer fabrication to final packaging. Each stage plays a vital role in ensuring the high performance, reliability, and longevity of COB LED strips. As the demand for efficient and high-quality lighting solutions continues to grow, COB technology remains at the forefront, offering significant advantages in a wide range of lighting applications. This detailed overview provides insight into the meticulous process of COB LED strip manufacturing and highlights the importance of precision and quality control in achieving optimal results.

If you need assistance from professionals, feel free to contact us. We are here to provide you with expert help and support for all your needs. Don't hesitate to reach out to our team for personalized assistance and solutions. We look forward to serving you.

Our sales will reply to you within 2 hours.