High Quality OEM/ODM LED Strip Manufacturer

High Quality OEM/ODM LED Strip Manufacturer

November 14, 2022 355

In the world of lighting, LED strip lights have gained immense popularity due to their energy efficiency, versatility, and vibrant illumination. However, with the market flooded with a plethora of options, it's crucial to distinguish high-quality LED strip lights from the rest. In this guide, we'll explore seven essential methods to help you make an informed choice and ensure your lighting investment shines bright for years to come.

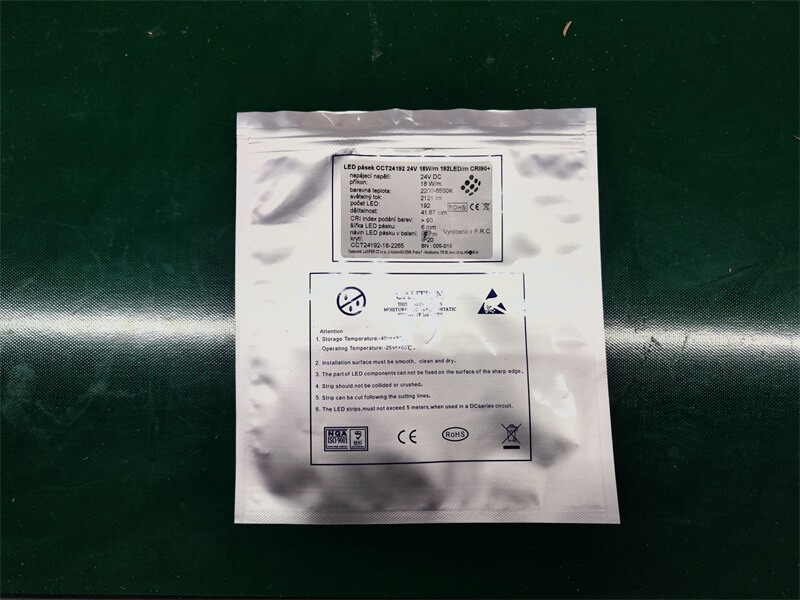

Reputable LED strip manufacturers employ anti-static packaging for their products. Typically, low-voltage 12V/24V LED strips come in 5-meter or 10-meter rolls, while high-voltage strips are spooled at 50 meters or 100 meters. These rolls are then sealed with anti-static and moisture-resistant bags for protection.

On the other hand, counterfeit or low-quality LED strips often cut costs by using recycled spools, and they may skip the anti-static and moisture protection in their packaging. A careful examination of the spools may reveal signs of removed labels and scratches on the surface.

In summary, legitimate LED strip manufacturers prioritize proper packaging to preserve the quality of their products, while subpar or counterfeit alternatives may compromise on protective measures to save on costs.

The LED light strip produced by the formal LED light strip manufacturer is SMT SMD process, produced with solder paste and reflow soldering process. Therefore, the LED strip solder joints are relatively smooth, the amount of solder is uniform and consistent, and the solder joints are curved from the FPC pad to the LED electrode.

Observing solder joints can provide preliminary insights into the quality of LED strip lights. Here are some indicative markers to help you assess the quality of LED strip lights:

Uniformity of Solder Joints: High-quality LED strip lights typically feature uniform solder joints. The spacing and size of solder joints should be consistent, with no obvious defects or irregularities.

Soldering Quality: Solder joints should be secure, showing no signs of loosening or cracking. Poor soldering can lead to LED chips coming loose or potential short-circuit issues.

Solder Joint Strength: Gently press the solder joints with your fingers or a tool to check if they are firmly affixed to the LED strip. High-quality solder joints will not become loose.

Absence of Impurities: Solder joints should be free from noticeable impurities, oxidation, or foreign substances. These issues can affect electrical connections and stability.

Solder Joint Placement: Solder joints should be correctly positioned on the LED strip, connecting to each LED chip. Any misalignment or incorrect positioning can impact the performance of the LED strip.

Clarity of Solder Joints: Solder joints should be clearly visible, with no blurred or hazy traces. Blurry solder joints may indicate a rough manufacturing process.

Identifying the quality of LED strip light FPC board needs to focus on the following key aspects:

1.Check the flexibility of the FPC board, high-quality FPC boards should be bendable enough to adapt to various installation scenarios.

2. Pay attention to the material uniformity of the FPC board to ensure that there are no visible imperfections, bubbles or uneven colors.

3. Check the thickness of the copper foil on the FPC board. A good FPC board should have a consistent thickness of copper foil to provide stable conductive properties.

4. Consider the high temperature resistance of the FPC board to ensure that it will not be deformed or damaged during prolonged use.

5. Check the oxidation resistance of the FPC board to ensure that it does not oxidize or become damaged easily in humid environments. Combining these factors can help you identify the quality of LED strip light FPC board.

To assess the quality of an LED strip, you can draw preliminary conclusions by examining its lifespan and warranty period:

Lifespan: High-quality LED strips typically have a longer lifespan. The lifespan refers to the expected duration of the LED strip's normal operation, usually measured in hours. The product specifications often clearly state the lifespan, and a longer lifespan typically indicates a more durable product.

Warranty Period: The warranty period is the timeframe during which the manufacturer offers repair or replacement services. Generally, high-quality LED strips come with longer warranty periods, indicating the manufacturer's confidence in the product's quality. In general, the longer the warranty period, the more willing the manufacturer is to stand behind the product's quality and performance.

High-quality LED light strips usually come with clear, detailed labeling information, including the manufacturer's name, model number, production date, certification marks (e.g., CE, RoHS, etc.), and technical specifications. This information can help you confirm product origin and compliance.

Check the included accessories, such as connectors and power adapters, for their look and feel. High-quality accessories are usually well-made and have a solid connection. If the accessories look cheap or easily damaged, it may be a sign of poor product quality.

Evaluating a company's focus on a specific product line and its years of operation often leads to a more reliable indicator of product quality. Companies with a long history of specializing in a single product tend to provide higher-quality offerings, as they have amassed substantial experience and established robust production and quality control processes. Additionally, the acquisition of qualifications and certifications such as ISO, CE, and RoHS underscores a company's commitment to meeting international standards and regulations, ensuring that their products possess a certain level of quality and safety performance.

The above are the 7 methods for identifying the quality of LED strip lights. We hope this information has been helpful to you. If you have any additional insights to share or if you have a need to purchase LED strip lights, please feel free to contact us. We are a reputable LED strip supplier based in China, with 12 years of experience and a steadfast focus on manufacturing various types of LED strip lights.

If you need assistance from professionals, feel free to contact us. We are here to provide you with expert help and support for all your needs. Don't hesitate to reach out to our team for personalized assistance and solutions. We look forward to serving you.

Our sales will reply to you within 2 hours.