High Quality OEM/ODM LED Strip Manufacturer

High Quality OEM/ODM LED Strip Manufacturer

July 9, 2023 317

LED strip lights have become a popular lighting solution due to their versatility, energy efficiency, and vibrant illumination. Have you ever wondered how these captivating light strips are produced? In this article, we will provide a detailed overview of the manufacturing process of LED strip lights. From selecting materials to final assembly, read on to discover the step-by-step journey of LED strip lights coming to life.

LED Chips: The process begins with selecting high-quality LED chips. These chips are typically made of semiconductors such as gallium arsenide (GaAs) or gallium nitride (GaN) that emit light when an electrical current passes through them.

Flexible Circuit Board: A flexible circuit board, usually made of a flexible copper-clad laminate material, serves as the base for mounting the LED chips. The flexible nature of the board allows it to conform to various shapes and enables easy installation.

Solder Paste and Components: Solder paste, a mixture of flux and tiny solder particles, is applied to the circuit board to establish electrical connections. Other components, such as resistors and capacitors, may also be added to control current, voltage, and other functions.

Encapsulation Material: An encapsulation material, often made of silicone or epoxy resin, is used to protect the LED chips and other components from external elements, such as moisture and physical damage. This material is applied over the circuit board, encapsulating the LEDs and forming a protective layer.

PCB Preparation: The flexible circuit board is cut to the desired length, taking into account the specific requirements of the LED strip light design. The board is then cleaned and prepared for the next steps.

Solder Paste Application: Using a stencil, solder paste is applied to the circuit board in the specific areas where the LED chips and other components will be placed. The solder paste acts as an adhesive and conductor during the soldering process.

LED Chip Placement: High-precision pick-and-place machines are used to accurately position the LED chips onto the solder paste-covered areas of the circuit board. The chips are carefully aligned according to the desired lighting pattern and secured in place.

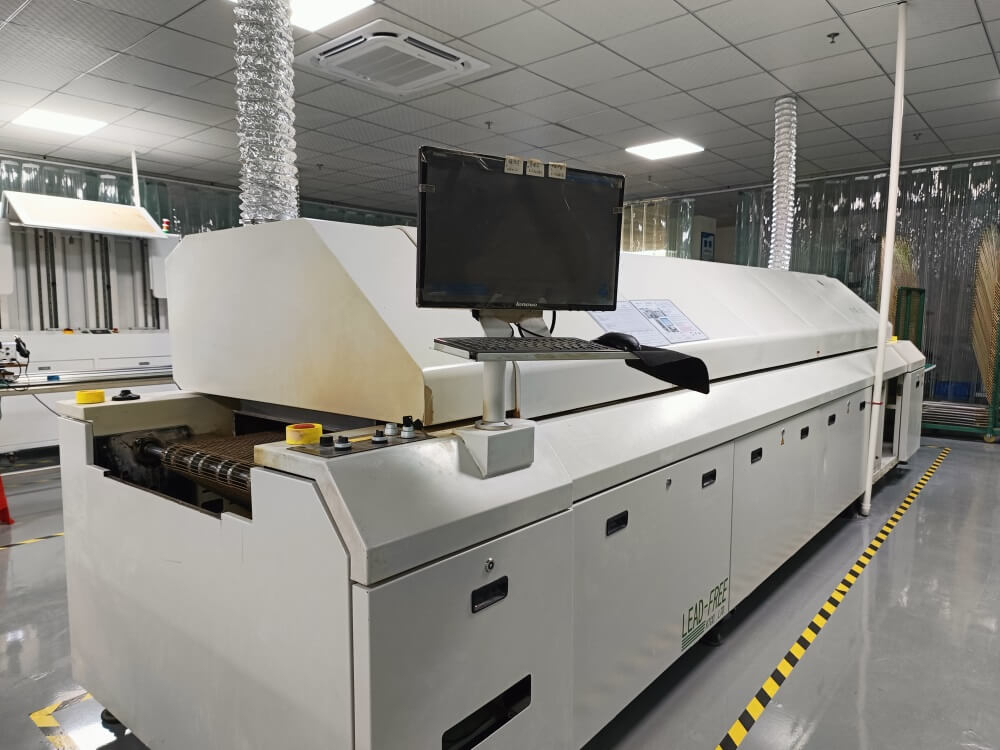

Reflow Soldering: The populated circuit board is subjected to reflow soldering. The board passes through a high-temperature oven, where the solder paste melts, creating strong electrical connections between the LED chips and the circuit board.

Encapsulation: The encapsulation material, such as silicone or epoxy resin, is dispensed over the LED chips and other components. This process ensures that the LEDs are fully protected and isolated from external factors, ensuring longevity and durability.

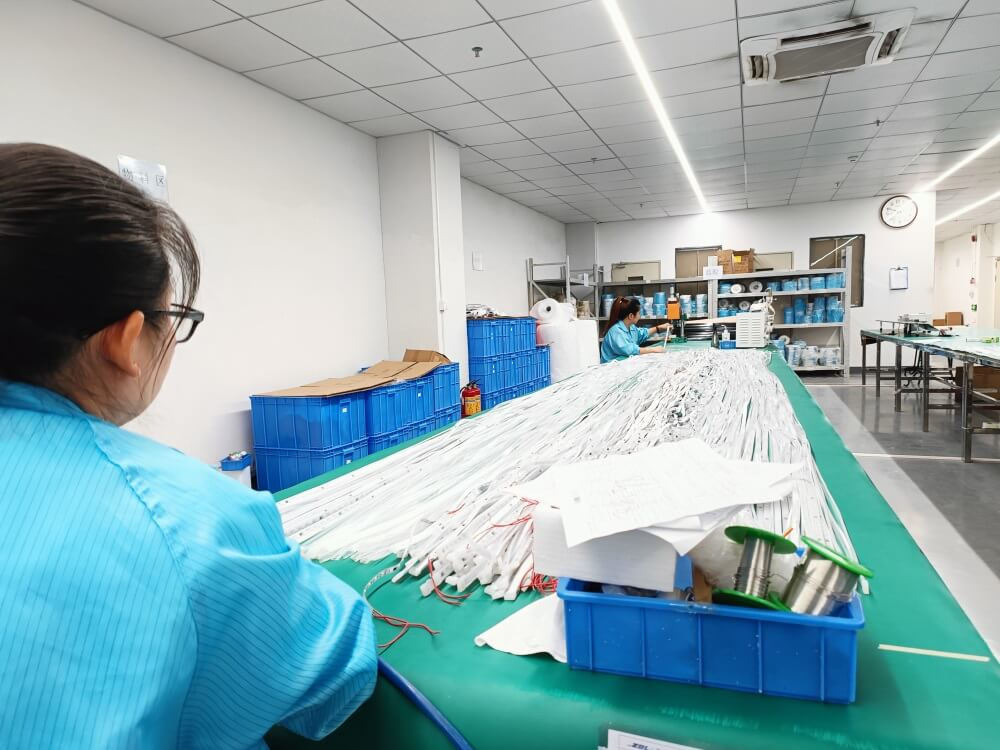

Cutting and Packaging: Once the encapsulation material has cured, the LED strip lights are cut into the desired lengths. They are then packaged, often on reels or in protective bags, ready for distribution and installation.

Quality control is a critical aspect of LED strip light manufacturing. Manufacturers follow stringent testing procedures to ensure product reliability and performance. Key quality control steps include:

Visual Inspection: Each LED strip light undergoes visual inspection to check for any defects or irregularities in components, soldering, and encapsulation.

Electrical Testing: LED strip lights are tested for functionality and electrical performance. Parameters such as voltage, current, color consistency, and brightness levels are measured to ensure adherence to specifications.

Aging and Endurance Testing: LED strip lights may be subjected to prolonged operation under controlled conditions to simulate real-life usage. This testing helps identify any potential issues related to performance, heat dissipation, or reliability.

Conclusion:

The manufacturing process of LED strip lights involves a meticulous journey from selecting high-quality materials and components to the final assembly and testing. The combination of precision machinery, soldering techniques, encapsulation, and rigorous quality control ensures the production of reliable and visually appealing LED strip lights.

Understanding the intricate process behind LED strip light production allows us to appreciate the craftsmanship and attention to detail involved. The result is a lighting solution that offers energy efficiency, versatility, and captivating illumination for a wide range of applications.

If you need assistance from professionals, feel free to contact us. We are here to provide you with expert help and support for all your needs. Don't hesitate to reach out to our team for personalized assistance and solutions. We look forward to serving you.

Our sales will reply to you within 2 hours.